GAS POWERED AIR CONDITIONING

Introduction

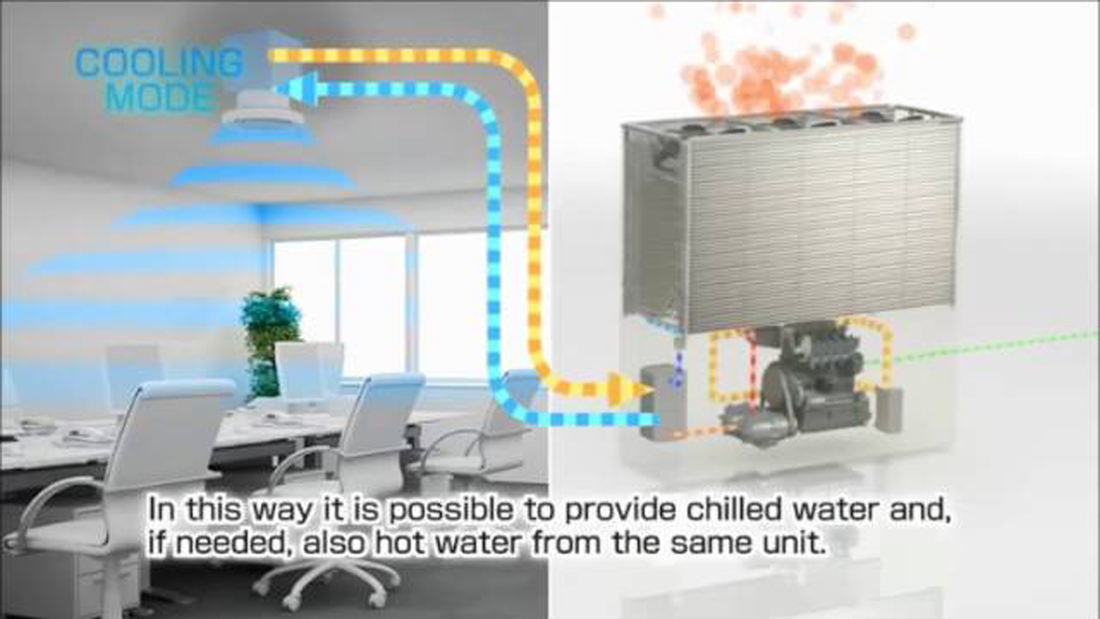

Yanmar’s Gas Powered Air Conditioners are multi-split systems, with one outdoor unit connected to a number of indoor units. In traditional electric multi-split systems, the compressors in the outdoor unit are powered by electric motors, but in the Yanmar system a small gas engine drives the compressors. In traditional electric systems, the electric motors change speed to match the varying heating or cooling requirement of the building. In the Yanmar system, the engine automatically changes speed to achieve the same result. These outdoor units are sometimes referred to as Gas Heat Pumps or GHPs.Yanmar have been building engines in Japan for over 100 years and they have developed a special range of gas engines to power these air conditioners. These are spark ignition piston engines (similar to a small car engine) and have been designed for low noise, long life and minimal maintenance. They only need servicing every 10,000 hours or 5 years.All the indoor components (ducted units, ceiling cassettes, wall mounted units, remote controllers etc.) are similar to that used by traditional electric multi-split systems, so the whole system looks and feels very familiar to users.

Background

Yanmar was one of the first manufacturers to develop gas engine driven air conditioners in Japan around 25 years ago and has been a market leader ever since. The Japanese government encouraged the development of these systems in the 1980s as a means to reduce the peak load on Japan’s electricity networks, a significant issue facing Australia’s energy industry today. Yanmar’s Gas Powered Air Conditioners have been sold in Australia and the South Pacific since 2008 and there are now hundreds of systems installed throughout the region. As the Distributor for this region, Yanmar Energy Australia has a team of qualified technicians to support the product and stocks all of the spare parts recommended by Yanmar.

Benefits

Using a gas engine to drive the air conditioning compressors reduces the electricity required byaround 90%. In many new building projects and building refurbishments, there is not enoughpower available to operate electric reverse cycle air conditioners, so money must be spent onupgrading the electrical services. These large costs can be avoided by installing gas powered airconditioning.For example, many school buildings were constructed 30 or 40 years ago. The power supply was adequate at the time, but these days classrooms need power for laptop computers, electronic whiteboards etc. If the school requires reverse cycle air conditioners for the classrooms, the original electrical supply may not cope. In a typical Yanmar installation, one 85kW outdoor unit can air condition 6 classrooms and 2 teacher prep rooms while drawing only 8 amps single phase.Meeting today’s environmental challenges means many building projects are required to reach a range of “Green” targets in order to obtain building approvals and/or attract the right tenants. The Yanmar gas powered system can assist greatly, as it reduces the outdoor unit’s greenhouse gas emissions by up to 50%. It also scores points for reducing peak demand and for using zero water.Energy costs are always a concern and gas powered air conditioning has provided savings of 30 to 50% versus the cost of similar electric outdoor units.In extremely cold weather, many electric reverse cycle units can struggle to provide the necessary heating because their condenser coils have iced up. The Yanmar gas powered units use waste heat from the engine to boost the heating performance, thereby avoiding these long de-icing cycles.